Choosing Reliable Partners: A Detailed Guide to pcb assembly manufacturers

Understanding the Growing Need for Modern PCBA Solutions

The electronics industry has grown at an exceptional pace, and every new digital device relies on high-quality printed circuit boards to operate efficiently. As a result, pcb assembly manufacturers play a major role in supporting innovation across industries such as consumer electronics, telecommunications, automotive systems, industrial automation, and medical technology. Choosing the right service provider can directly influence product reliability, speed to market, and overall manufacturing costs. This is why businesses today carefully evaluate their PCBA partners before entering long-term production contracts.

What Defines a Professional PCB Assembly Partner

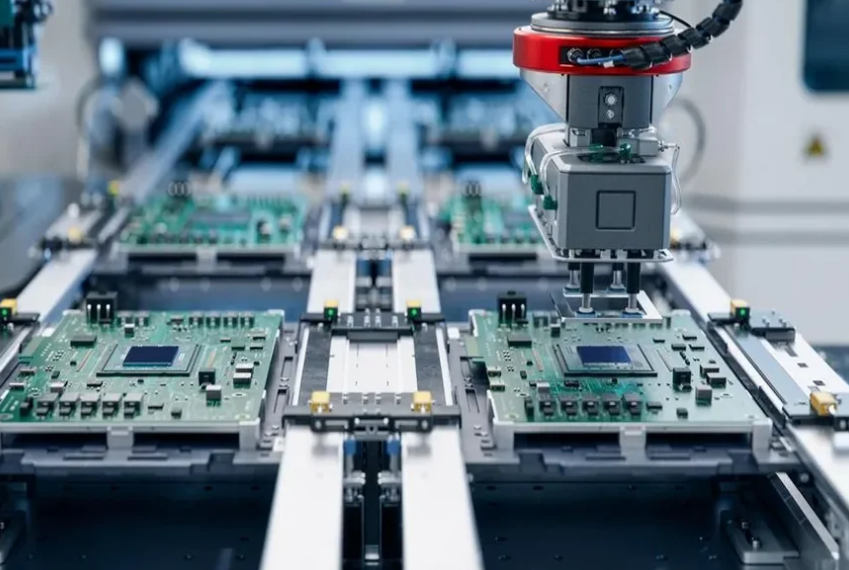

A reliable assembly service provider must meet strict standards in production accuracy, component handling, and testing. The first indicator of professionalism is a streamlined workflow designed to avoid errors during component placement or soldering. Advanced pick-and-place machines, skilled technicians, controlled soldering environments, and precise inspection equipment all contribute to high-quality assembly.

Additionally, well-organized documentation practices help avoid communication gaps. Professional pcb assembly manufacturers create clear production files, track revisions carefully, and maintain strict quality control logs for every order.

Capabilities That Set Manufacturers Apart

Every business has different project needs, so understanding the capabilities of a manufacturer is important before choosing who to work with. Modern assembly providers offer multiple services, such as SMT assembly, through-hole assembly, mixed-technology assembly, and prototype development. Some also handle high-density interconnect boards and small-scale, custom-designed boards.

Manufacturers with advanced capabilities can support multilayer PCBs, fine-pitch components, BGA installation, and precise reflow processes. This flexibility allows clients to shift from prototype to mass production without switching vendors, saving time and ensuring consistency.

Importance of Quality Certifications in the PCBA Industry

Certifications are a strong indicator of a company’s commitment to quality and process control. Most reputable pcb assembly manufacturers follow standards such as ISO 9001 for quality management and RoHS compliance for environmentally safe production. Some even follow IPC standards for soldering and assembly practices, which ensures consistent workmanship and reliable output.

Manufacturers serving medical, automotive, or aerospace industries may also follow specialized certifications. These certifications demonstrate their ability to meet the strict reliability demands of high-risk applications.

Why Component Sourcing Matters

Component sourcing affects both performance and production time. If a manufacturer purchases components from unreliable suppliers, the final product may suffer from quality issues such as overheating, signal distortion, or premature failure. That is why top assembly providers work with trusted component distributors and maintain efficient supply chain processes.

Some pcb assembly manufacturers also provide full turnkey assembly, meaning they handle sourcing, purchasing, assembly, and testing. This service reduces the burden on clients, ensures smoother project management, and helps avoid supply delays.

The Role of Automated and Manual Inspection

Inspection is one of the most critical stages in PCBA manufacturing. Automated Optical Inspection systems check for solder faults, misalignments, short circuits, and missing components. In addition to automated methods, many high-level manufacturers include manual visual inspections conducted by skilled technicians.

Some also offer X-ray inspections to verify hidden solder joints, especially for BGA components. Thorough inspection ensures that every PCB functions as expected and meets the required performance standards.

Understanding Cost Factors in PCB Assembly

The cost of assembling a board depends on several variables, and a reliable manufacturer explains these factors transparently. Key cost drivers include board size, number of layers, quantity of components, complexity of the design, and required testing procedures.

While it is tempting to choose the lowest-cost provider, sacrificing quality often leads to higher repair and maintenance costs later. The best pcb assembly manufacturers balance affordability with accuracy, making them long-term partners for growing businesses.

See also: Brushless DC Technology: Innovations and Applications

How Lead Time Affects Production Planning

Fast delivery is essential for companies working on tight product development schedules. Manufacturers with automated production lines and efficient workflow management deliver faster turnaround times without compromising quality.

Some providers allow clients to choose between standard, expedited, and rapid prototyping services. Clear communication regarding lead times helps prevent delays in product launches and enables smooth coordination across design, engineering, and supply teams.

Importance of After-Sales Support and Technical Assistance

PCBA projects often require technical discussions, clarifications, and troubleshooting. Manufacturers who offer ongoing customer support make it easier for clients to refine their designs and ensure that production meets expectations.

Reliable pcb assembly manufacturers also provide failure analysis reports, improvement suggestions, and engineering feedback to optimize future batches. This level of cooperation builds trust and strengthens long-term business relationships.

Choosing the Right Manufacturer for Your Industry

Each industry has unique requirements. For example, medical devices require strict testing, while consumer electronics focus on affordability and fast production. Automotive applications demand high-temperature resistance and long-term reliability.

Understanding these needs helps businesses choose a manufacturer with relevant experience and equipment. Many assembly partners showcase their specialized industry expertise, making it easier for clients to evaluate compatibility.

Benefits of Long-Term Partnerships With PCBA Providers

Working with the same assembly provider over time delivers consistent quality across multiple production runs. It also allows both parties to understand each other’s processes, which reduces errors and speeds up project execution.

Long-term relationships often result in better pricing, priority scheduling, and customized service packages. Professional pcb assembly manufacturers value customer loyalty and continually invest in improving service quality.

Conclusion: Making the Right Choice for Your Electronics Projects

The success of any electronic product depends heavily on the quality of the boards inside it. That is why selecting dependable pcb assembly manufacturers is one of the most important decisions a business can make. By evaluating capabilities, certifications, quality practices, and customer support, companies can find a manufacturing partner who delivers precision, efficiency, and long-term value.