The Role of Aluminum CNC Machining Parts in Precision Engineering

Introduction to Aluminum CNC Machining

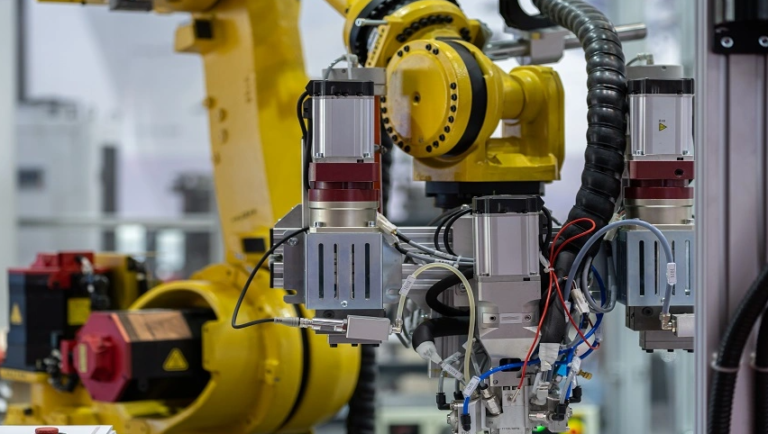

In today’s industrial environment, the demand for precision and high-performance components is greater than ever. Aluminum cnc machining parts have emerged as a key solution for manufacturers seeking accuracy, durability, and efficiency. These components combine the lightweight and corrosion-resistant properties of aluminum with the precision offered by CNC (Computer Numerical Control) machining.

CNC machining allows the creation of complex geometries and tight tolerances that are essential in industries like aerospace, automotive, electronics, and medical devices. The ability to automate production while maintaining consistent quality makes aluminum cnc machining parts an indispensable resource in modern manufacturing.

Benefits of Aluminum CNC Machining Parts

Lightweight with High Strength

Aluminum cnc machining parts are valued for their low density, which reduces the overall weight of machinery or vehicles. Lightweight components are crucial in sectors such as aerospace and automotive, as they contribute to higher efficiency and better performance. Despite being light, aluminum provides sufficient strength and structural stability for demanding applications.

Precision and Consistency

CNC machining ensures that aluminum parts are produced with exceptional precision. The ability to maintain tight tolerances minimizes assembly errors and enhances the performance of the final product. Additionally, CNC technology aluminum cnc machining parts allows for repeatability, enabling manufacturers to produce large volumes of components with consistent quality.

Corrosion Resistance and Durability

Aluminum naturally resists corrosion, making it suitable for applications exposed to moisture, chemicals, or extreme temperatures. Aluminum cnc machining parts maintain their integrity over time, reducing maintenance costs and extending the lifespan of equipment or devices.

Thermal and Electrical Efficiency

Aluminum possesses excellent thermal and electrical conductivity. CNC machined parts are often used in electronics and other applications where heat dissipation or conductivity is important. Precision machining ensures that these components meet exact design specifications, enhancing functionality and performance.

See also: Rejuvenating Skin with Modern Technology

Industrial Applications

Aerospace

Aluminum cnc machining parts are widely used in aerospace for brackets, housings, structural supports, and engine components. Their lightweight nature reduces fuel consumption while maintaining safety and performance standards. CNC machining ensures components meet strict aerospace tolerances.

Automotive

Automakers use aluminum cnc machining parts for engine components, transmission housings, and structural elements. Reducing vehicle weight improves fuel efficiency and handling, while CNC precision ensures that parts fit seamlessly and perform reliably over time.

Medical Devices

The medical industry demands extremely accurate components. Aluminum cnc machining parts are utilized in surgical instruments, diagnostic devices, and housings for medical electronics. CNC machining allows manufacturers to meet stringent tolerances, ensuring safe and effective performance.

Electronics and Consumer Products

Aluminum’s lightweight and conductive properties make it ideal for electronic housings, heat sinks, and structural frames for consumer devices. CNC machining enables the production of complex designs that enhance cooling, durability, and overall performance.

Manufacturing Process

Selecting the Right Aluminum Alloy

The choice of aluminum alloy affects the properties of the final product. Commonly used alloys include 6061, 7075, and 2024, each offering distinct characteristics in strength, corrosion resistance, and machinability. Selecting the appropriate alloy is essential to meet application-specific requirements.

CNC Machining Techniques

Aluminum cnc machining parts can be manufactured using several processes:

- Milling: Removes material to produce flat surfaces, slots, and intricate geometries.

- Turning: Creates cylindrical parts with precise dimensions.

- Drilling: Produces accurate holes for assembly and functionality.

- Finishing: Processes such as grinding, polishing, and deburring enhance surface finish and dimensional accuracy.

These processes are computer-controlled, ensuring high precision and efficiency.

Quality Control

Quality assurance is essential in producing aluminum cnc machining parts. Measurement tools such as coordinate measuring machines (CMMs), micrometers, and calipers are used to verify dimensions, tolerances, and surface finish. Rigorous inspection ensures that each part meets the required standards before being delivered.

Design Considerations

Wall Thickness and Strength

Designing appropriate wall thickness ensures structural integrity while keeping weight low. Proper design prevents deformation and guarantees durability under operational stresses.

Tolerances and Fit

Accurate tolerances are critical to ensure proper assembly and function. CNC machining provides the precision necessary for components to fit together seamlessly.

Surface Finish

Surface finish impacts both performance and aesthetics. Smooth finishes reduce friction in moving assemblies and enhance the appearance of consumer-facing products.

Complexity vs. Cost

While CNC machining allows for complex designs, overly intricate parts may increase production costs and time. Balancing complexity with manufacturability is essential for efficiency and cost-effectiveness.

Advantages Over Alternative Materials

Aluminum cnc machining parts offer a superior balance of lightweight, strength, and corrosion resistance compared to steel or plastic. Steel provides higher strength but adds weight and is more difficult to machine, while plastic is lightweight but lacks durability and thermal stability. Aluminum provides a versatile and high-performing solution suitable for diverse applications.

Future Trends

Automation and Smart Manufacturing

The integration of automation, AI, and IoT in CNC machining enhances efficiency, reduces errors, and ensures consistent quality. These advancements enable faster production and lower costs while maintaining high standards.

Advanced Aluminum Alloys

Emerging aluminum alloys with improved strength, corrosion resistance, and thermal properties are expanding the possibilities for cnc machining parts in high-performance applications.

Sustainable Manufacturing

Sustainable practices, such as aluminum recycling and energy-efficient machining processes, are becoming increasingly important. These methods reduce environmental impact while maintaining the quality and precision of components.

Conclusion

Aluminum cnc machining parts are essential in modern manufacturing for their precision, strength, lightweight, and versatility. Industries including aerospace, automotive, medical, and electronics rely on these components for high-performance and reliable solutions. With ongoing advancements in CNC technology, material science, and sustainable practices, aluminum cnc machining parts will continue to play a crucial role in the future of precision engineering.